EXCELLENCE

PARMAMODA

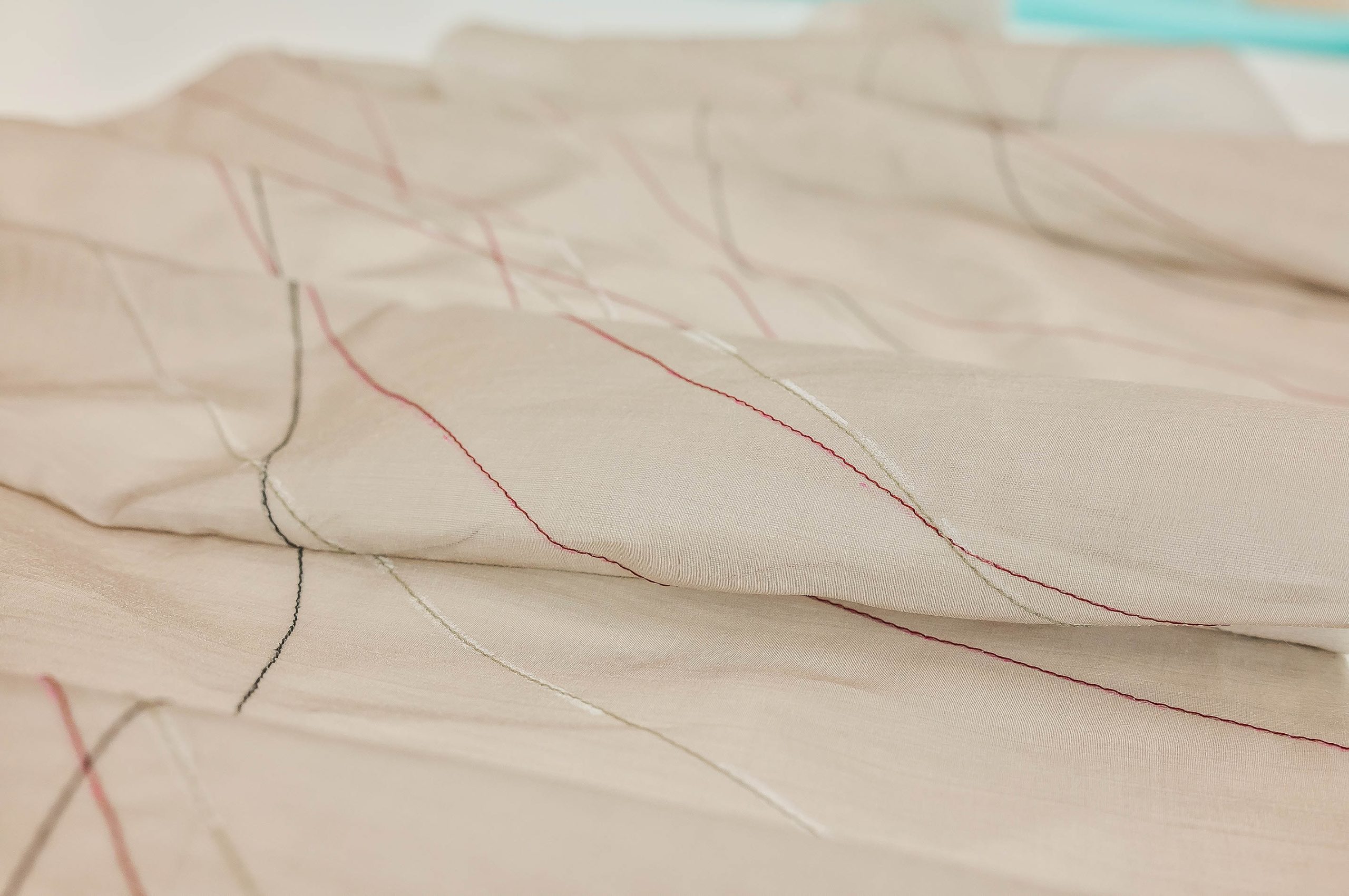

The value of lightness

Parmamoda is a company renowned for its superb ability to create exclusive garments, using impalpable fabrics expertly crafted to turn creative dreams into reality.

EXQUISITELY “LIGHT” TAILORING

Specialized in the production of women’s lightweight apparel. Thanks to an avant-garde pattern-making department and in-house quality control, the company guarantees the utmost attention to every detail of the end product, distinguishing itself for highly refined workmanship and expert knowledge of delicate fabrics.

SERVICES

For more details, explore Auxilium, Gruppo Florence’s sustainable core where the Group’s vision meets companies’ tangible objectives.

IF YOU ARE LOOKING FOR COLLABORATION OPPORTUNITIES, GENERAL INQUIRIES OR SIMPLY WANT TO START A BUSINESS CONVERSATION